Read our Latest Industry Report: Aerospace

Aerospace components demand extreme precision, advanced materials, and flawless quality. These are challenges that push traditional machining to its limits. This report explains the reasons why water jet cutting is becoming indispensable in this sector.

Key Takeaways:

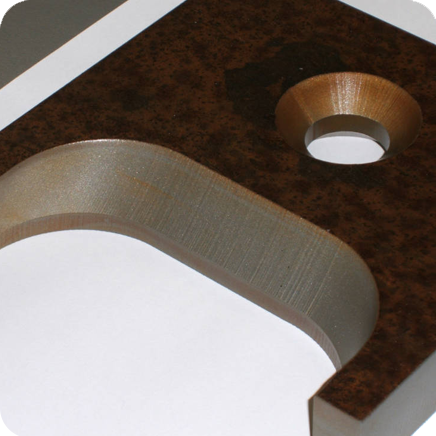

Precision Without Heat: Cuts metals, composites, and polymers without distortion, microstructural changes or tool wear.

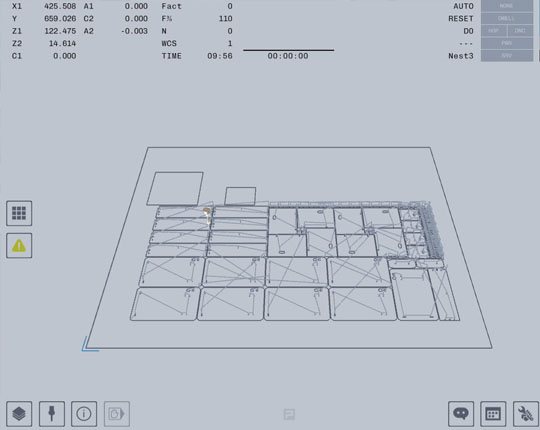

Handles Complexity: 3- and 5-axis systems tackle curves, bevels and compound angles in a single pass.

Fast, Flexible Production: Ideal for rapid prototyping, short runs and multi-material jobs.

Digitally Integrated: Seamlessly connects to CAD/CAM, process logging and Industry 4.0 systems.

Cost- and Eco-Efficient: Minimises scrap, lowers energy use and reduces post-processing.

For aerospace engineers and manufacturers, water jet cutting isn’t just a tool, it’s a strategic advantage for precision, speed, and sustainability.

To learn more download the full report below.