World Class Waterjet Cutting Systems

Water Jet Sweden develop, design and build world class water jet cutting machines. All of our water jet cutting machines are built to order in Sweden where starting at entry-level we customise our proven technology to offer a range of 100+ machine configurations. With exceptional build quality our professional water jet cutting machines are built to last ensuring optimum ROI.

How we helped our client decide which machine

Multi-head cutting solution increases throughput by massive 70% and reduces processing costs by 30% per piece

Water Jet Sweden UK recently secured an order from a customer who needed to produce slots in 75mm thick high tensile steel bars, with volumes at several hundred per month.

A single head machine was specified by the customer however, by carrying out cutting tests, we demonstrated that using our Superstream cutting heads available pump capacity could be better utilised by cutting with two heads, rather than the more traditional single, large nozzle. This enabled an increased throughput of 70% and a reduction of processing costs of 30% per piece.

Our Water Jet Cutter Models

You can find more information on our different water jet cutter models by clicking on the links below. However, with all our water jet machines are built to order and a range of 100+ machine configurations available we do highly recommend you give us a call on 01937 845499 to discuss your specific needs. We can then advise on the best model and options for your business.

Water Jet Cutter Industries & Applications

We're the first choice for industry professionals across a diverse range of applications. Our world-class machines are found in a wide range of industries but our customers share a desire for advanced solutions in water jet cutting where high-quality build, superior components, high service standards, and 20+ year machine lifetime are required.

Cut a wide range of materials, from Kevlar composites, used in personnel & vehicular armour to heavy plate steel up to 250mm. Production of small vanes using Microcut technology, blanking Titanium plate for wide chord fan blades, and trimming to near nett shape of 3D formed blades.

Cut a wide range of metals up to 300mm thick using the same process including aluminium, titanium, yellow metals, inconels, monels, duplex steels as well as wear and armour plate grades

General Fabrication & Sheet Metal Cutting

Produce accurate profiles in a wide range of material types and thicknesses, ideal for lower batch sizes and more bespoke designs.

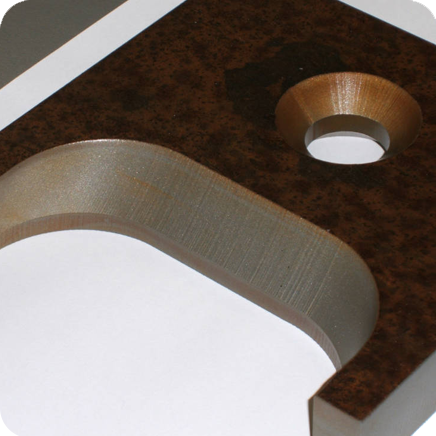

Stone, Ceramic & Glass Cutting

Cut anything from a thin ceramic tile through to 250mm granite. Decorative inlays from materials such as stainless steel, brass, copper, and contrasting stone can be cut on same machine.

Ideal for OEM and aftermarket manufacturers. Materials such as laminated graphite and thin metallic gaskets can be processed without damage to the parent material with no heat-affected zone and burr-free.

Cut materials such as inconels, hastelloys and stainless steels up to 250mm thick. High reliability due to no heat-affected zone (HAZ) in the parent material and produces finished or near to nett shape parts.

We build your machine to order specific to your industry/application

Take a look at some Waterjet Sweden machines in action

Waterjet cutting new height sensor

Linear Z Axis Waterjet Cutting

Watejet Sweden Water Wheel Cutting

Water Jet Sweden Clients

At Water Jet Sweden UK we have the expertise and knowledge to satisfy the most demanding waterjet cutting machine requirements.

Here’s just a small selection of Water Jet Sweden UK clients:

We provide direct sales, service and support to the UK market and support 100+ water jet cutting systems in the UK which include Rolls Royce, Titanium International and Airproducts Plc.

Customers come from a wide range of industries but share a desire for exceptional customer value, and the benefits our machines and service can offer in terms of time, money, product quality and sustainability.

NIKAB: From powersport star to international industrial entrepreneur

NIKAB is a fast-growing industrial services company based in Sweden working mostly in service and maintenance, refurbishment, and new construction as well as consulting services. Two young powersport aces lead the business with the same courage, creativity, and persistence that has characterised their sporting careers.

Buying a Water Jet Cutting Machine FAQs

How does a water jet cutting machine work?

A water jet cutting machine uses highly focused water jets for cutting work. This non-thermal cutting process is as follows:

• Ordinary tap water is filtered and pressurised in an Ultra High-Pressure pump then fed into the cutting heads with several thousand bar pressure.

• A small diameter orifice concentrates the water beam and the pressure turns into velocity. The supersonic water beam cuts all kinds of soft material like plastic, foam, rubber and wood. The cutting heads move according to a fixed pattern over the material.

• To increase the cutting power, grains of an abrasive are added to the stream and the water beam turns into high-speed sandpaper cutting all kinds of hard materials like stone, glass, metal and composites.

Where can I get support for my Water Jet Sweden waterjet cutting machine?

If you have problems with your water jet cutting machine, Water jet Sweden UK is always available for you.

• 24 hours support via our hotline

• Large UK stock of Original Spare Parts

• Custom-made comprehensive service and maintenance contracts

• Support for expansion and relocation

• On-site training

How much does a Water Jet Sweden water jet cutting machine cost?

The costs of a water jet cutting machine vary greatly with the requirements of the customer and are therefore always determined individually. Important information on the following points:

- Desired size of the working zone

- Desired number of cutting heads

- Desired cutting method (2D / 3D)

- Material to be processed

A water jet cutting machine can also be equipped with a range of function tools and features at an added cost to support your specific production requirements.

In addition to purchase costs, the cost of water, electricity, abrasives and wear parts should be taken into account in the planning.