Learn More About Water Jet Cutting

Use water jet cutters to cut virtually any material quickly and precisely in any shape or size including metals, stone, glass, wood and plastics.

Water jet cutting is a non-thermal cutting method using only natural sand and water to cut almost any material. The brittle cutting process give a smooth cutting surface with no slag or heat affected zones, and there is less need for post processing.

All materials can be cut by the same water jet machine, from soft rubber and plastics to the hardest metals and ceramics. A CNC operated water jet cutter ensures identical parts independent of volumes and with a minimum of waste material. The versatility and ease of operation makes waterjet technology incomparable to any other machine tool process in the market.

How Does Waterjet Cutting Work?

Tap Water Turns Into Jet Beam

It all starts with ordinary tap water. It is filtered and pressurised in an Ultra High-Pressure pump, then delivered via high-pressure tubes to the waterjet cutting head. A small diameter orifice will concentrate the water beam and the pressure turns into velocity. The supersonic water beam cuts all kinds of soft material like plastic, foam, rubber and wood. This process is called Pure Water Jet Cutting (PWJ).

Abrasive Adds Power

To increase the cutting power, grains of an abrasive is added to the stream and the water beam turns into high-speed sandpaper cutting all kinds of hard materials like stone, glass, metal and composites. This process is called Abrasive Water Jet Cutting (AWJ). For micro components and really narrow cuts there is the Fine Abrasive Water Jet process (FAWJ), based on the same principles as AWJ.

Why Choose Water Jet for Cutting?

When calculating overall production costs, waterjet has repeatedly come out as the most profitable cutting method compared to traditional thermal methods.

When is Water Jet Cutting a Good Fit?

Talk to us about your needs and requirements, let us assist in finding the right solution for your business.

With a precision of 0.1 mm, the surface can be made so smooth that there is no or very little need for additional processing.

With the cold waterjet cutting method, the material will always keep its characteristics. No micro cracks, stress and hardened surfaces. This also eliminates impact by dust, toxic gases and deformation by slag and dross.

A pure waterjet beam makes thin incisions of 0.1-0.25mm. An Abrasive Water Jet makes 0.4-1mm wide cuts, in up to 300mm thick solids at a tolerance of 0.025mm. The FAWJ cutting head on Micro cutting gives a 0.2mm incision at the extreme tolerance of 0.1mm!

You can cut different materials and shapes from prototypes to serial production with simple programming, the same cutting tool and a very short set up time.

Waterjet systems can cut a comprehensive range of materials and thicknesses without thermal impact on the material.

Waterjet cutting is ideal for preparation of parts before milling. Cut two dimensional solids quickly and easily to save both processing time and tool wear.

When the EDM tolerances are no required, waterjet cutting is a cost-efficient complementary cutting method. The water jets also cut non-conducting materials like composites and glass.

Waterjet repeatedly comes out as the most profitable cutting method compared to traditional thermal methods when calculating overall production cost.

Got any questions? There are lots of FAQs here or just use the contact button to ask!

Materials Suitable for Water Jet Cutting

Metals

Metal cutting by Abrasive Water Jet Cutting (AWJ) is a major area of application for water jet cutting technology. Finely grained sand combined with the ultra-high pressure water beam creates a powerful cutting tool, capable of cutting up to 300 mm thick metal into any shape. This is a cold cutting process with fine cuts and very little additional work needed. The metal remains unchanged metallurgically, there are no heat-affected zones and no smoke or vapours are given off.

Composites

Today composites come in many forms including carbon fibre reinforced plastic; fibreglass; and composite foams, Kevlar, carbon fibre, glass fibre, non-woven materials, composite resins, etc. An abrasive waterjet’s supersonic erosion can cut nearly any material reliably and precisely in any direction to incredible detail without any dust or gas being emitted and the low contact force eliminates the need for bulky tooling.

Glass

Waterjet is the fastest and most cost-effective way of processing glass which requires shaping and/or internal cutouts. One process is used to quickly transition from design to cut without tool changes. Cutting, contours and profiles can be produced that are too difficult/costly using conventional separation methods. The continuous increase/decrease in cutting pressure when cutting materials such as glass or ceramics, enables material damage to be avoided.

Stone, Tiles & Ceramics

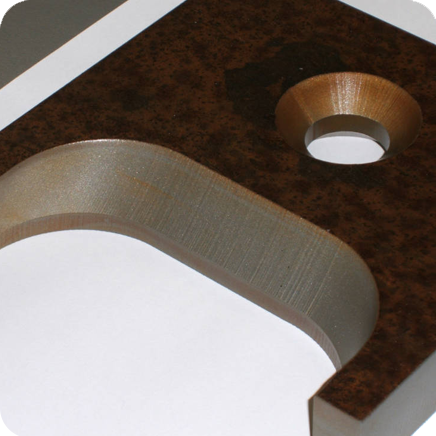

Water jet cutting can be used to cut thick granite, marble, sandstone, porcelain, tiles, concrete, gypsum plasterboards, insulation materials and mosaics for architectural designs like floors, walls, ceilings and counters as well as artistic work. Using a water jet machine for free-cutting, you can easily transform most stone materials into almost any shape without breakage thanks to the stepless increase or decrease in cutting pressure.

Rubber, Plastics & Foam

When cutting soft materials you don't need abrasives with a water jet cutter. Instead pure water jet cutting process (PWJ) cuts rapidly with very narrow cuts of 0.1 mm bringing benefits for both small- and large-scale production. There's no need for punching tools with simple CNC programming able to produce one single part quickly. And with a beam you can mount a large number of parallel cutting heads, thus cutting very large volumes simultaneously.

Wood

The wood materials most frequently used today are fabricated ones such as veneer and plywood. Fast setup time, narrow cuts, no splintering and easy free-form cutting are some of the documented benefits when applying water jet cutting for these materials. With a water pressure of up to 6,000 bar, even the thickest wood can be cut precisely, without any thermal changes, no heat influences and no smoke or vapours given off. With microjet, cutting the finest geometries are possible.

Please contact us with any questions you may have or take a look at our FAQs here

Water Jet Cutter Industries & Applications

We're the first choice for industry professionals across a diverse range of cutting applications. Whilst our world-class machines are found in a wide range of industries, what our customers share is a desire for advanced solutions in water jet cutting where high-quality build, superior components with high service standards, and 20+ year machine lifetime are required.

Cut a wide range of materials, from Kevlar composites, used in personnel & vehicular armour to heavy plate steel up to 250mm. Production of small vanes using Microcut technology, blanking Titanium plate for wide chord fan blades, and trimming to near nett shape of 3D formed blades.

Cut a wide range of metals up to 300mm thick using the same process including aluminium, titanium, yellow metals, inconels, monels, duplex steels as well as wear and armour plate grades

General Fabrication & Sheet Metal Cutting

Produce accurate profiles in a wide range of material types and thicknesses, ideal for lower batch sizes and more bespoke designs.

Stone, Ceramic & Glass Cutting

Cut anything from a thin ceramic tile through to 250mm granite. Decorative inlays from materials such as stainless steel, brass, copper, and contrasting stone can be cut on same machine.

Ideal for OEM and aftermarket manufacturers. Materials such as laminated graphite and thin metallic gaskets can be processed without damage to the parent material with no heat-affected zone and burr-free.

Cut materials such as inconels, hastelloys and stainless steels up to 250mm thick. High reliability due to no heat-affected zone (HAZ) in the parent material and produces finished or near to nett shape parts.