Waterjet Cutting Driving Shop Productivity

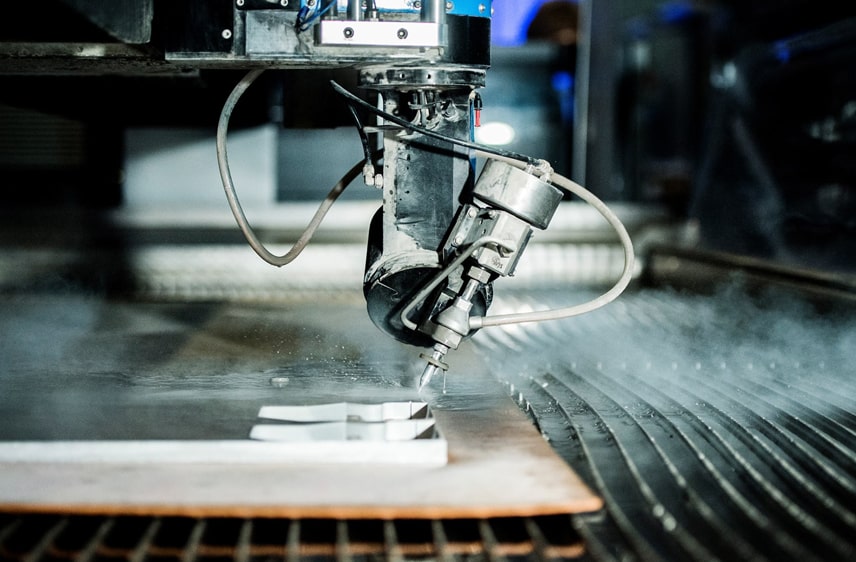

The growing need in the manufacturing industry for more advanced applications and the versatility of waterjet technology is a key reason why water jet cutting is now being used far more on shop and factory floors, often replacing machine tools.

The 3D cutting capabilities of waterjet broadens the range of potential applications, “Manufacturing shops can expand the types of material they process with waterjet to materials such as composite and advanced aerospace alloys,” explained Gavin Bell, General Manager of Water Jet Sweden.

Bell added, “Waterjet cutting is increasingly being selected because manufacturers want to invest in technology that provides their business with increased flexibility. Added to that, waterjets have become faster, more accurate, and less expensive to operate.”

For most shops, faster cutting results in higher throughput; better accuracy means they can tackle more applications with tighter accuracy requirements; and equipment that is less expensive to operate means a better return on investment.

Manufacturing is also shifting from the traditionally held break-fix mentality. Manufacturers now want optimum uptime and reliability to enable more predictable maintenance schedules for their waterjet cutting machines.

Efficiency and intelligence are key trends driving waterjet technology today. “It’s about rapid diagnosis of problems, how to quickly fix those problems and taking the subjectivity of the operator out of the maintenance equation. Uptime is key to productivity and profitability,” said Bell.

Waterjet users have several key priorities to improve and optimise waterjet technology:

• Improved cutting speed

• Abrasive and water utilisation and management

• Predictability and length of maintenance intervals as well as downtime

• Reduced total cost of ownership

• Improved serviceability

• Reduced capital cost

• Improved ease of use and ease of setup

• Increased energy efficiency

Software & Connectivity

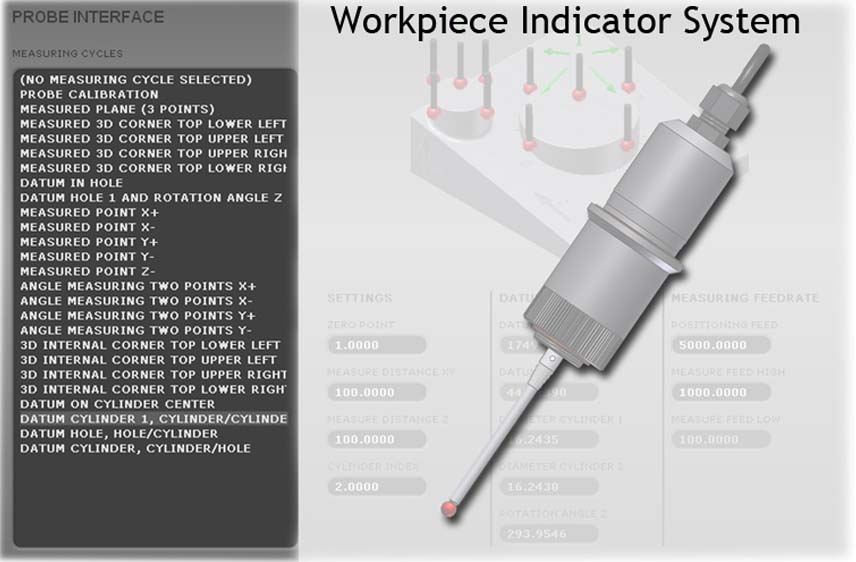

A recent AMRC report suggested that the key driver in the increased popularity of waterjet machines in the manufacturing industry is the improvement in software which plays a vital role, not only in connecting factory-floor machines but also in making it easier for relatively inexperienced users to programme the cutting and achieve the desired result.

“Connected machines can supply data such as predictive maintenance intervals and optimised machine operation for specific jobs to continually improve the cutting process. Linking all of that data provides improved efficiency, accuracy, and reliability of waterjet systems,” explained Bell.

“And by employing modern software design principles, a new and more intuitive user experience is provided allowing less need for waterjet-specific expertise, faster user learning, and significantly more flexibility for automation of the workflow.”

The impact of this improved efficiency enables shops to increase production and produce better quality parts while simultaneously improving the reliability of their manufacturing process. Software is also critical in the emergence of newer applications, such as smaller parts or even micro-sized parts that shops are now manufacturing with the latest waterjet cutting machines.

With ultra-precise cutting methods and the ability to leave a smooth edge lasers are often considered an alternative to waterjet cutting but they also transfer enormous amounts of heat into a workpiece as they cut it. This results in a large HAZ that extends out from the site of the cut and can potentially affect the physical properties of the workpiece to have an adverse effect on the final product. Because waterjet cutting doesn’t transfer nearly as much thermal energy, it is ideal for avoiding issues related to HAZ. To meets parts tolerances particularly in new and experimental composites manufacturing, waterjet cutting is therefore proving to be the ideal part cutting solution.

Waterjet Accuracy for Precision Cutting in Manufacturing

In many machine shops, the accuracy of a process can be vital for ensuring the functionality of a completed part or product. For example, manufacturers supplying aerospace companies often must meet parts tolerances as precise as +/- 0.005” to avoid creating a fatal flaw in an aircraft. If such tolerances aren’t met, then the part is rejected and, if a manufacturer can’t meet part tolerances consistently, then their clients will look elsewhere for their high-precision parts.

So, to retain customers and grow revenues, many machine shops need the most accurate methods for cutting and shaping parts which waterjet technology can deliver. Relatively speaking, water jet cutting process is highly accurate. Once the cutting starts (meaning that the initial through hole is complete), a waterjet cutting machine can achieve a parts tolerance of +/- 0.001” with consistency. This makes the waterjet cutting process highly desirable for cutting precision parts.

Extending Reliability, Uptime

Waterjet machine operators almost universally rank machine reliability and ease of use as a priority. “Reliability is always first and foremost, then ease of maintenance and simplification of the waterjet cutting process,” commented Bell.

“Whilst waterjet technology is gaining in popularity in the cutting industry due to its wide capabilities, historically it had an unfair reputation of having high operating costs as well as being high maintenance,” Bell said.

He continued, “Through the deployment of smart, efficient waterjet machines we reduce the risk and cost of human error. And developments in software, precision cutting and machine reliability gives machine owners the automation and predictability they need from their equipment enabling improved productivity, streamlined operations and planned preventative maintenance. Our constant focus on machine efficiency delivers a smoother running operation, less downtime, and gives manufacturers more time to focus on their business."

About Water Jet Sweden

Water Jet Sweden develops, manufactures and markets advanced solutions for water jet cutting and provides a quality aftermarket offer with service and parts. Since 1993 they strive to be the obvious first choice for customers worldwide who seek solutions in water jet cutting of high quality and high technical content.

For more information on how we can increase your throughput and reduce your processing costs with our world-leading water jet cutting technology or to get a quote on any of our waterjet cutting machines just call us on 01937 845499 or send us an email to info@wjsuk.com

November, 2025

November, 2025