New technologies simplify the jet engine manufacturing process

When fabricating jet engine turbines, Wire EDM is often used, since the technology provides narrow cuts for precise and complex shapes. The flip side of the coin is that Wire EDM is a time-consuming manufacturing process, in both setup time and processing. It’s also a thermal manufacturing process which influences the properties of the material. Both of these issues can now be solved by using new and innovative waterjet cutting technology.

Fabricating turbines for jet engines is a time-consuming process that requires extreme precision. Since Wire EDM is recognised as a relatively slow machining technology, an international jet engine supplier explored the possibility of reducing the manufacturing time of fixed turbine parts by replacing wire EDM with other processing technologies. The challenge was to find a technology that could meet the tough requirements.

First thermal cutting technologies such as laser and fibre laser were tested, but these had to be rejected because these were found to have too much heat impact on the material.

The next step was to investigate waterjet technology as an potential solution. The drop-shaped contours of the jet turbine required five-axis machining and at the same time a very narrow cut to handle small contours, sharp corners, small tolerances, with a fine cutting surface.

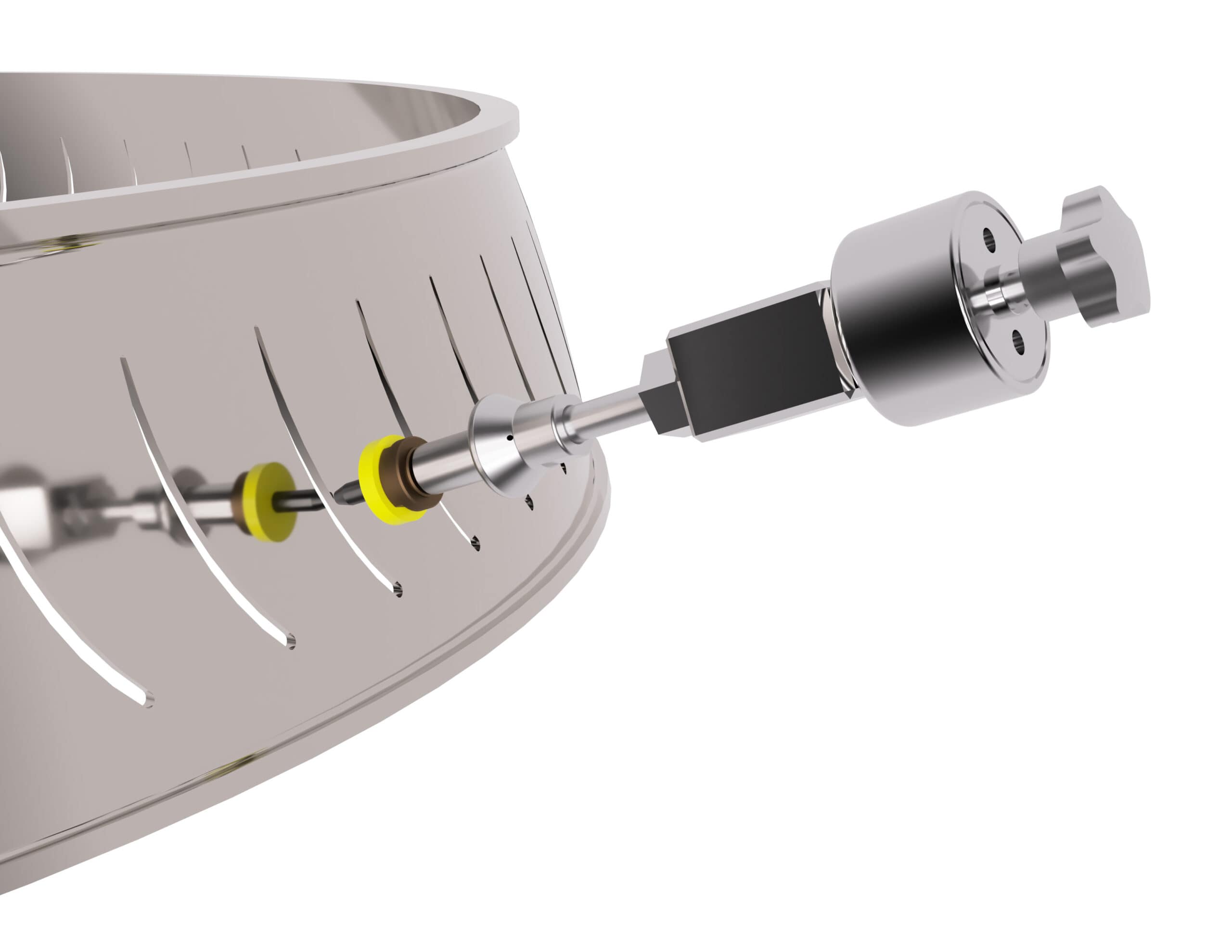

Traditional waterjet cutting was difficult to apply, however the new FiveX Ultra from Water Jet Sweden provided a viable opportunity. The FiveX Ultra is a full 3D cutting machine (0-120˚ cutting) designed to manage high precision cutting assignment. As the FiveX Ultra can be equipped with a FAWJ Micro Cutting Tool it also manages extremely fine cuts down to 300 my, for precise and complex shapes.

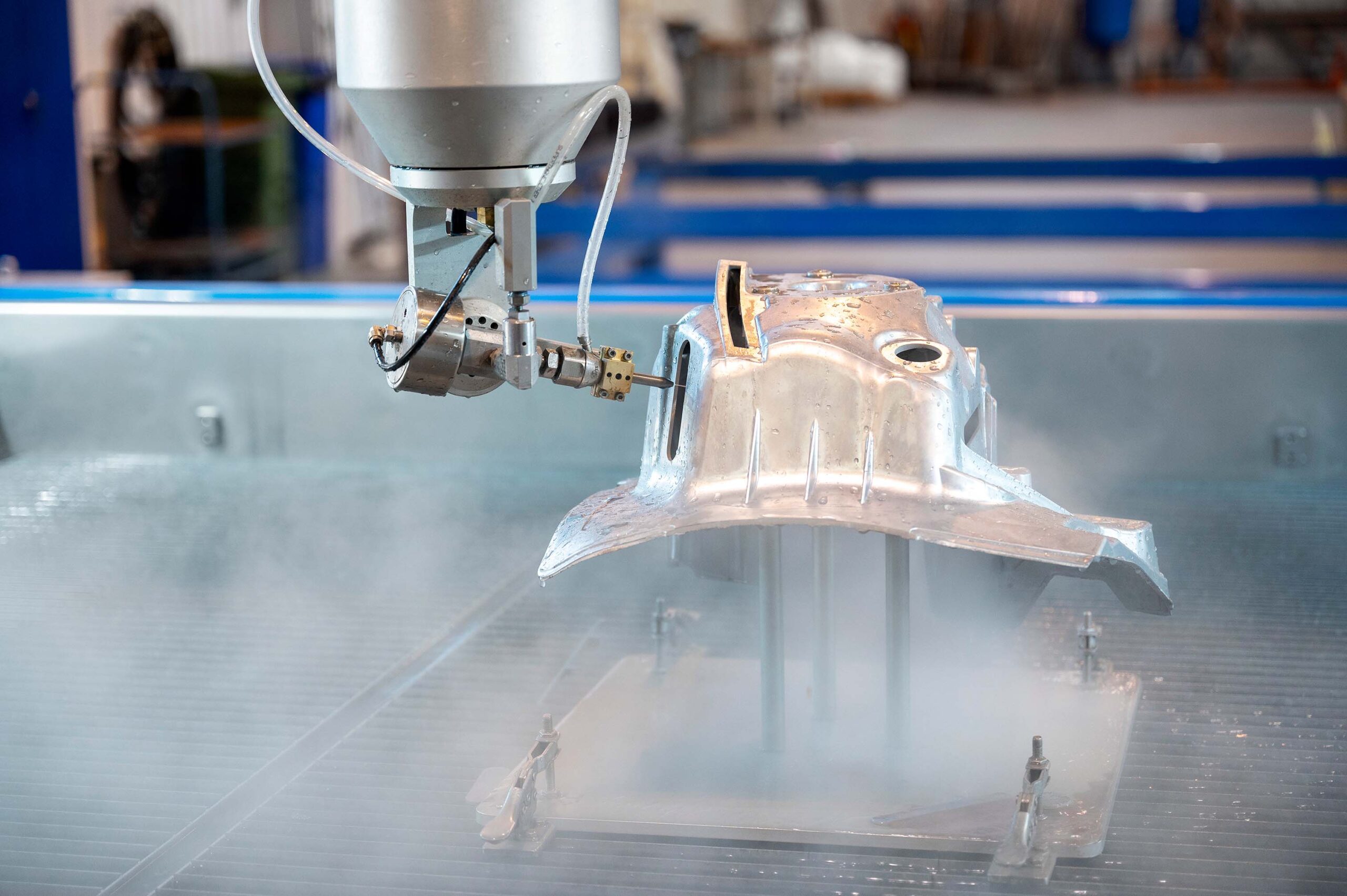

After visiting the Water Jet Sweden Demo Centre, in Ronneby Sweden the development of a new manufacturing routine for jet engine turbines began.

Parameters are defined to enable jet engine turbine production using waterjet technology

Waterjet cutting is a cold cutting process, so heat-affected zones are avoided ensuring the cutting surface remains satin smooth. The narrow cutting beam of the micro cutting tool enabled it to cut sufficiently sharp corners, however adjustments had to be made to the slightly cone-shaped cutting beam, which is a characteristic of waterjet cutting. The TVL function (tapered angle control, variable speed and delay compensation) was therefore fine-tuned to achieve an approved final cutting profile.

Another challenge in the work process was that it wasn’t possible to make direct measurements of the parts however a solution was found using interpreters to check the contour accuracy. In small steps, the process was gradually optimised to finally get the correct and precise profile.

Tony Ryd, Co-founder and CTO at Water Jet Sweden commented, “We have developed a process to optimise cutting parameters for turbine production, using a unique combination of our new 3D waterjet cutting machine and our FAWJ micro cutting tool.”

There was also time saving in several steps of the manufacturing process. Not only was the cutting time improved but setup time could be reduced to a minimum, with fixtures instead of time-consuming wiring, and a new auto calibration tool reducing the time from loading to production start significantly.

“Turbine manufacturers around the world who want to save time and money, are welcome to contact us. We have a unique solution combined with extensive experience of efficient waterjet machining for industrial use,” concluded Tony Ryd.

FiveX Ultra with micro cutting head is unique frontline technology for advanced waterjet cutting

Fine tuning parameters in Water Jet Sweden Demo Centre in Ronneby, Sweden

About Water Jet Sweden

Water Jet Sweden develops, manufactures and markets advanced solutions for water jet cutting and provides a quality aftermarket offer with service and parts. Since 1993 they strive to be the obvious first choice for customers worldwide who seek solutions in water jet cutting of high quality and high technical content.

For more information on how we can increase your throughput and reduce your processing costs with our world-leading water jet cutting technology or to get a quote on any of our waterjet cutting machines just call us on 01937 845499 or send us an email to info@wjsuk.com

June, 2025

June, 2025