Multi-head cutting solution for client increases throughput by massive 70% and reduces processing costs by 30% per piece

WJS UK recently secured a UK order for their Water Jet Sweden model NCH30. The customer needed to produce slots in 75mm thick high tensile steel bars, with volumes at several hundred per month.

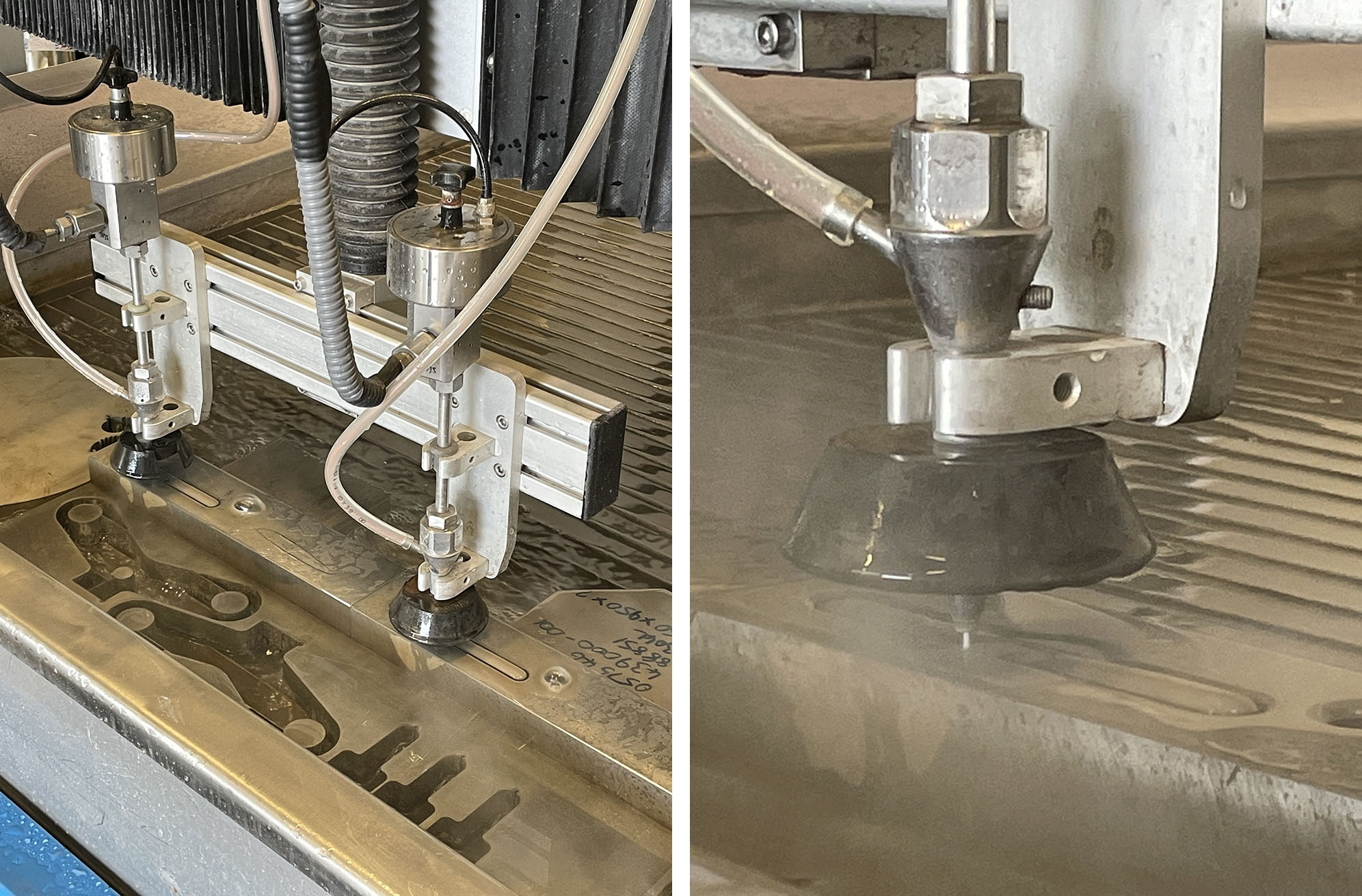

Initially the customer had specified a single head machine based on what most of the market was promoting. However, by carrying out cutting tests, the experts at Water Jet Sweden demonstrated that by using their Superstream cutting heads, they could better utilise the available pump capacity by cutting with two heads, rather than the more traditional single, large nozzle.

This proposed alternative solution from WJS UK enabled throughput to be increased by 70% and processing costs to be reduced by 30% per piece. Not only that, since Water Jet Sweden machines are readily adaptable and pre-prepared to utilise additional cutting heads and other ancillary tools, there was only a small additional cost increment to achieve these benefits.

With electricity prices soaring and predicted to continue rising through to the end of 2023, the customer opted for the BFT Servotron 45Kw intensifier pump to provide the high-pressure water. The Servotron pump from BFT is certified by TUV as being 24% more energy efficient than the traditional AC Motor driven pumps during typical operation.

With no pressure spikes when the cutting head closes, this pump can be operated at full working pressure while reducing failures in the high-pressure components due to fatigue. The higher operating pressure in this case provides 10% faster cutting speed, so for every part produced there is a further 10% saving in processing costs and 10% more availability of the equipment for production.

All Water Jet Sweden machines feature:

Extra wide linear bearings to resist torsion and provide a stable platform

Heavy duty steel frame that is stress relieved after fabrication and then precision machined

Completely enclosed bellow protection for all dynamic motion systems and motion parts, simplifying maintenance and prolonging the lifetime of the machine

Linear drives in the X-Axis have twice the speed of a ballscrew, with greater positioning accuracy and zero backlash when changing direction for cutting performance

Key Benefits of Water Jet Sweden machines:

Reliability and Accuracy

Water Jet Sweden has consistently transformed ground breaking research and development technology into a comprehensive product range with over 700 installed water jet machines throughout the world.

Highest Technical Standards

By using components that have been tested over many years and manufactured using the latest techniques, in high pressure water jet cutting and drive engineering fields, Water Jet Sweden offers CNC machines of the highest technical standard

World Class

The worldwide patent for the integrated guide system, high performance cutting heads and valves, as well as collaborative work with the world’s leading control suppliers Fanuc and Siemens, has made it possible to manufacture a full range of 2D and 3D CNC water jet equipment with the maximum accuracy and performance.

Dedicated R&D

The research and development of new technology, components and software is carried out in an impressive facility in Southern Sweden, together with the latest developments in CAD/CAM software. When compared to conventional water jet cutting machine running costs Water Jet Sweden machines are not only state-of-the-art but extremely cost effective and efficient.

For more information on how we can increase your throughput and reduce your processing costs or to get a quote on any of our waterjet cutting machines just call us on 01937 845499 or send us an email to info@wjsuk.com

November, 2025

November, 2025