Like a brand new machine after 21 years

Ronny Martinsson, Water Jet Sweden Customer Services Manager inspecting the machine, packed and ready for delivery.

"Quality never goes out of style," they say. Well for Water Jet Sweden cutting machines quality never goes out of performance either! A recent refurbishment of a 21-year-old waterjet cutting machine to almost new condition by our in-house team demonstrated this perfectly making it ready for many more years of quality cutting.

In 2001, Water Jet Sweden sold the machine to a Norwegian waterjet contract cutter. After 21 years of cutting, they decided to upgrade their workshop by investing in a new machine. Like many other well-maintained machines from Water Jet Sweden, the performance was still good, and a general "facelift" could be worth the investment. Customer Service Team at Water Jet Sweden seized the opportunity and bought the old machine.

"We have supported the customer since the machine was delivered in 2001, and have good knowledge of both operating hours and service history," says Ronny Martinsson, Customer Service Manager at Water Jet Sweden.

Looking at the refurbished machine, it is difficult to imagine that it has been in production for 21 years. Although it looked a little more run-down than when purchased, after a thorough cleaning, the potential was clearly visible. Every renovation project is different: this time the frame was repainted, new table grids were installed, hoses were replaced and, most importantly, the electrical system was replaced with a new Fanuc CNC system. The system change included everything from cables, motors and electrical cabinets to a modern PanelOne® Operator Panel.

"Of course, there is a difference between a completely new and a refurbished machine, but Water Jet Sweden's machines often still have many years of production capacity left, even after 20 years in operation, says Ronny Martinsson. Since 1993, none of our machines have been taken out of production due to substandard performance," Ronny continues.

The refurbished machine is now ready for delivery to a new customer in Germany, a forging company that will use the machine as a workstation in their workshop. The refurbished machine cost about 60% of what an equivalent new machine would cost.

"We provide lifetime support to all our machines, so maybe in 21 more years it will be time for a second "facelift", says Ronny Martinsson with a smile. Quality machines are good for your long-term business as well as for the environment," Ronny sums up.

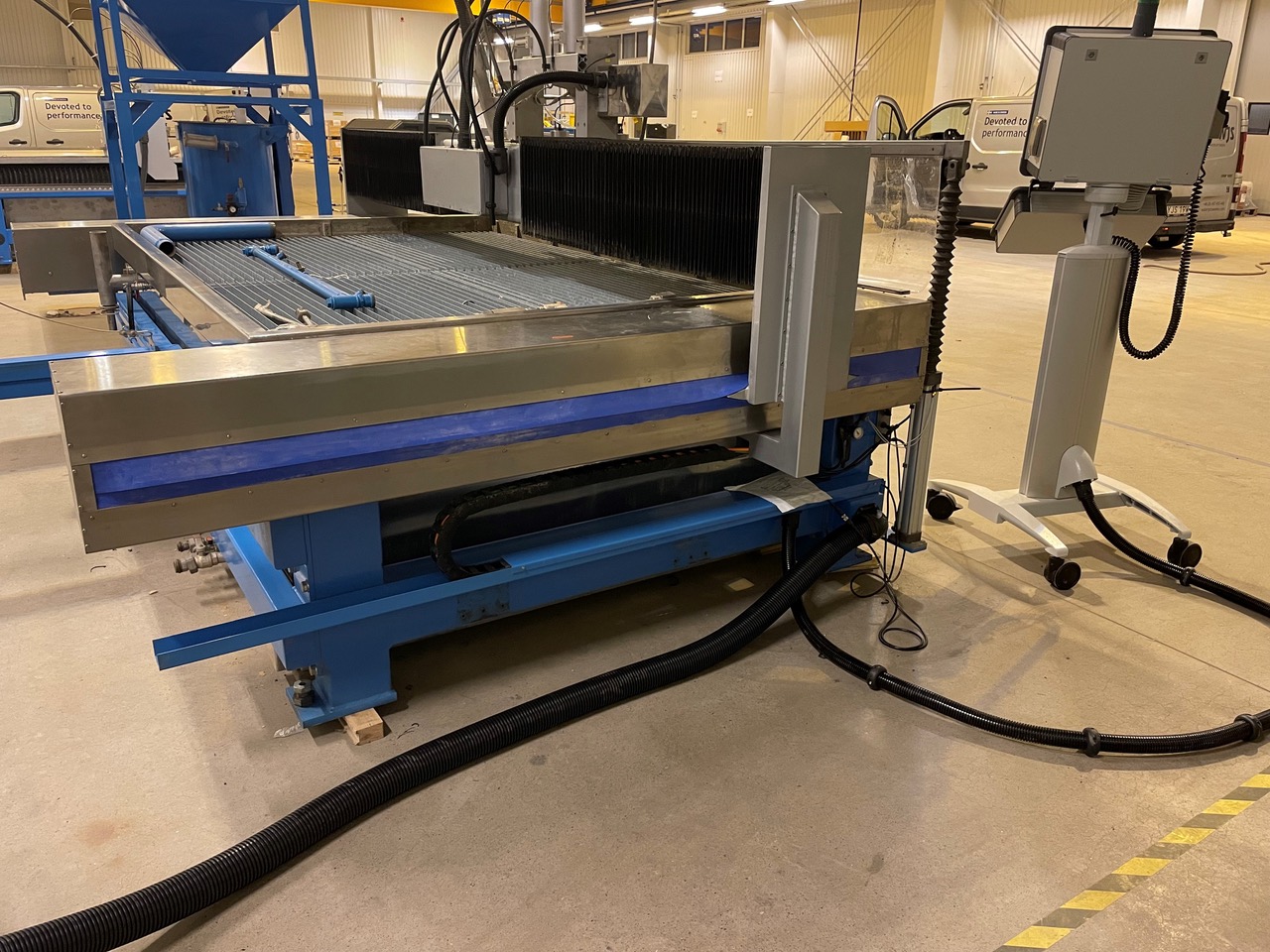

The machine looks brand new, after 21 years of operation.

The machine is completely renovated, on all sides.

Equipped with new cables and a new operator panel.

Electrical cabinet for the new Fanuc CNC system.

About Water Jet Sweden

Water Jet Sweden develops, manufactures and markets advanced solutions for water jet cutting and provides a quality aftermarket offer with service and parts. Since 1993 they strive to be the obvious first choice for customers worldwide who seek solutions in water jet cutting of high quality and high technical content.

For more information on how we can increase your throughput and reduce your processing costs with our world-leading water jet cutting technology or to get a quote on any of our waterjet cutting machines just call us on 01937 845499 or send us an email to info@wjsuk.com

November, 2025

November, 2025