Charles Day (Steel) invests in a state-of-the-art Water Jet Sweden BevelJet 60 Machine.

Established over four decades ago in the heart of Sheffield, the city of steel, Charles Day Steels has recently invested in a new Beveljet 60 water jet cutting machine from Water Jet Sweden.

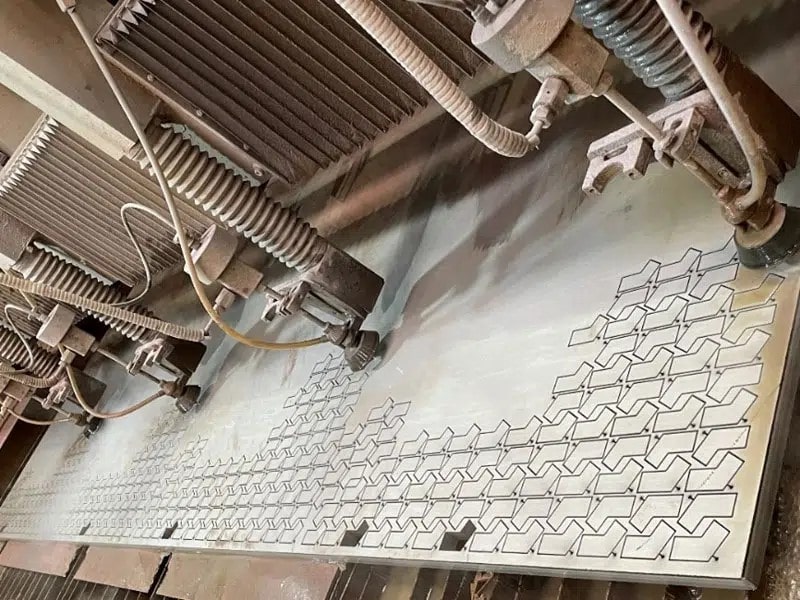

Now equipped with some of the most profound machinery available in both the laser cutting and metal profiling industries the Water Jet Sweden BevelJet 60 complete with a full 5-axis provides extremely versatile capability for both bevel and free form cutting. Combined with a 125hp pump the BevelJet 60 cutting head provides Charles Day with unrivalled capabilities and record lead times for an exceptional service every time. With typical waterjet pumps on average only producing 3,000-4,000 bar of cutting pressure from 50-60hp, this new pump can produce 6,200 bar of cutting pressure through two heads simultaneously using the massive 125hp, providing their customers with an incredibly time and cost-efficient waterjet cutting process.

Regarded as one of the most advanced pieces of machinery available in the metal profiling industry, this innovative piece of technology is the newest addition to Charles Day’s suite of state-of-the-art profiling machines.

Charlie Day, grandson of the founder and sales and business development director at Charles Day, said: “We are already experts in waterjet cutting and have been offering the service for over 20 years now, but the addition of the Water Jet Sweden BevelJet 60 cutting head opens a whole new market for us. Not only can we provide large 2D parts on a quick turnaround, but now we can offer large 3D parts, again at a dramatically increased cut speed, at a competitive price.”

The increase in efficiency and capability, coupled with their BSEN 1090 EXC4 accreditation, also Charles Day to comfortably service both the nuclear industry, and the aerospace industry in accordance with ISO9100.

Key Benefits of the Water Jet Sweden BevelJet 60

The Water Jet Sweden BevelJet 60 stands as a testament to cutting-edge engineering and precision, and is a viable alternative to traditional metal profiling methods for cutting harder materials and machined parts.

3D Cutting Prowess

One of the standout features of the Bevel Waterjet is its remarkable cutting head, which can process parts at angles of up to 60 degrees. This extraordinary capability allows for the creation of intricate 3D shapes with unparalleled precision.

High-Pressure Dominance

Equipped with a 125hp pump operating at 6200 bar, the Waterjet Sweden BevelJet 60 is a true powerhouse in the world of cutting technology. Its engineering prowess enables it to seamlessly slice through materials known for their formidable hardness, including the likes of Wear Plate and Hardox.

Reduced production times with Simultaneous Dual Heads

What sets this machine apart is its dual-head configuration (one 3D and one 2D) that facilitates simultaneous cutting at high pressure through each head. This innovative approach dramatically reduces production times, offering expedited results without compromising the quality of the final product.

Precision Through Pressure Control

The Bevel Waterjet’s ability to adjust pressure offers a unique advantage. It ensures rapid cutting while maintaining the utmost accuracy and consistency in every cut, regardless of the complexity of the design.

Spacious Cutting Bed

To accommodate a wide variety of projects, the machine boasts a generously sized cutting bed measuring an impressive 4m x 8.5m. This expansive workspace is particularly valuable for industries that require ample room for intricate work.

About Water Jet Sweden

Water Jet Sweden develops, manufactures and markets advanced solutions for water jet cutting and provides a quality aftermarket offer with service and parts. Since 1993 they strive to be the obvious first choice for customers worldwide who seek solutions in water jet cutting of high quality and high technical content.

For more information on how we can increase your throughput and reduce your processing costs with our world-leading water jet cutting technology or to get a quote on any of our waterjet cutting machines just call us on 01937 845499 or send us an email to info@wjsuk.com

November, 2025

November, 2025